AI in manufacturing, biotech, pharmaceuticals, and automotive→ what is it?

AI in manufacturing, biotech, pharma, and automotive is the application of sophisticated algorithms and machine learning techniques to mimic human intelligence in machines, therefore enabling them to carry out activities including decision-making, pattern recognition, and predictive analysis.

Artificial Intelligence (AI) refers to the application of advanced algorithms and machine learning techniques to replicate human intelligence in machines, enabling them to perform activities such as decision-making, pattern recognition, and predictive analysis. In industries including manufacturing, biotech, pharmaceuticals, and automotive, artificial intelligence (AI) changes conventional processes by improving efficiency, accuracy, and creativity.

- In manufacturing, artificial intelligence minimizes expenses and downtime by optimizing production lines, predictive maintenance, and quality control.

- By examining complicated biological data, AI in biotech speeds up research, genome editing, and tailored therapy.

- In pharmaceuticals, artificial intelligence simplifies manufacturing, clinical trials, medication research, and supply chain management, hence greatly cutting time-to-market and enhancing compliance.

- AI in automotive industry drives smart production, predictive maintenance, and autonomous driving, hence improving safety and operating efficiency.

These uses taken together propel digital transformation in many sectors, hence allowing more intelligent, quicker, and cheaper operations. Including artificial intelligence is not only a technical improvement→ it is a basic change that changes how businesses create and compete in the modern day.

Applications of AI in Manufacturing, Biotech, Pharma, and Automotive

| Sector | Key AI Applications |

|---|---|

| Manufacturing | Predictive maintenance, quality control with computer vision, production scheduling, supply chain optimization |

| Biotech | Genome editing optimization, drug discovery acceleration, personalized medicine, biological data analysis |

| Pharma | Drug discovery and design, clinical trial optimization, manufacturing automation, anomaly detection, digital twins |

| Automotive | Autonomous driving systems, predictive maintenance, smart assembly lines, supply chain and inventory management |

AI’s capacity to process enormous information and learn from them enables these sectors to boost efficiency, minimize errors, and innovate at unprecedented speeds.

As AI continues to advance, its applications expand, making industries more nimble and responsive to market needs.

Evolution of AI in Industrial Sectors

The emergence of AI in industrial sectors has been distinguished by progressive integration from basic automation to powerful cognitive systems→

- Early stages involved rule-based automation concentrating on repeated operations.

- The advent of machine learning provided systems capable of learning from data, enabling predictive analytics and adaptive control.

- Deep learning and computer vision produced improvements in quality inspection and anomaly detection.

- Today, generative AI and digital twins model complicated processes and optimize operations in real time.

In pharma, for example, AI has gone from simple data analysis to complex drug discovery systems that cut the usual drug development cycle from over a decade to only a few years. Similarly, manufacturing has evolved from mechanized assembly lines to AI-driven smart factories that self-optimize and identify mistakes before they occur.

The voyage of AI in industry is a testament to ongoing innovation, turning formerly theoretical concepts into real instruments that transform entire value chains.

This content incorporates your keywords naturally and retains a neutral, encyclopedic tone ideal for your target audience in the US, UK, Singapore, Canada, China, Russia, and Colombia. Let me know which heading or sub-header you wish to proceed with next!

Core Technologies Powering AI Adoption

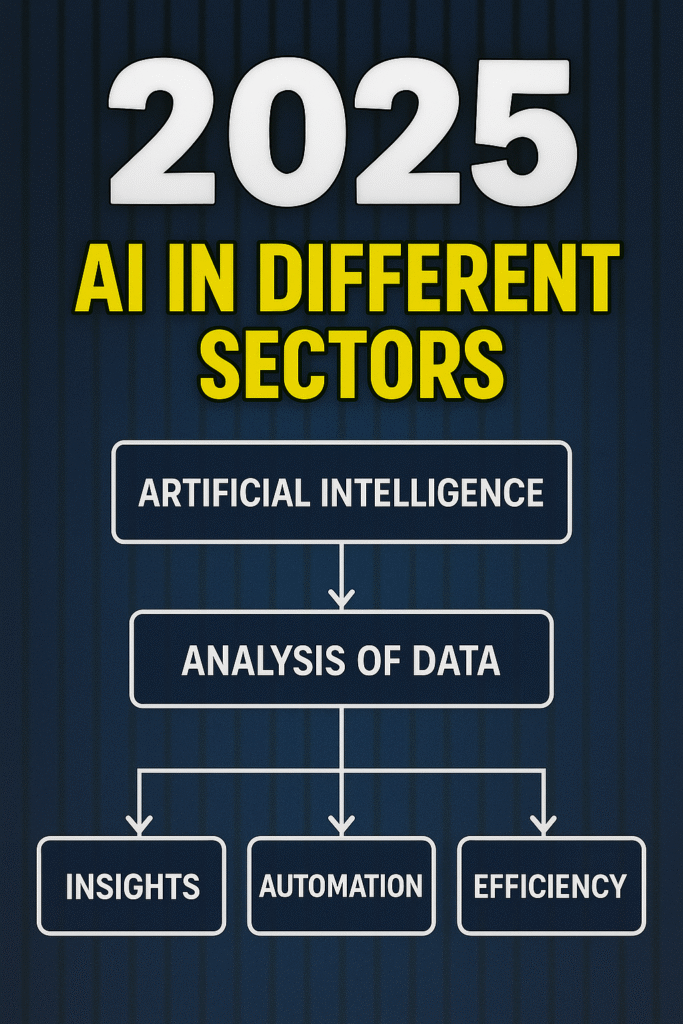

AI adoption across industrial, biotech, pharma, and automotive sectors is driven by a foundation of advanced technologies that enable machines to process data, learn from patterns, and make decisions autonomously.

- Machine Learning (ML)→ ML algorithms allow systems to learn from previous data and improve over time. In manufacturing, ML supports predictive maintenance and quality control. In biotech and pharma, it accelerates drug discovery and optimizes clinical trials.

- Deep Learning→ This subset of ML employs neural networks to evaluate complicated datasets, such as photos or genomic sequences. Deep learning is vital for computer vision in manufacturing and protein structure prediction in biotech.

- Natural Language Processing (NLP)→ NLP enables AI to interpret and synthesize human language, supporting applications like automated documentation, regulatory compliance, and customer service across sectors.

- Computer Vision→ By analyzing visual input from cameras and sensors, computer vision systems automate inspection, defect identification, and even autonomous vehicle navigation in automotive and manufacturing.

- Internet of Things (IoT)→ IoT devices capture real-time data from machines, cars, and laboratory apparatus. This data feeds AI models for monitoring, predictive analytics, and process improvement.

- Robotics and Intelligent Automation→ Robotics linked with AI enables smart automation in assembly lines, lab operations, and logistics, boosting efficiency and precision.

- Digital Twins→ Digital twins produce virtual versions of actual assets or processes. These models allow for simulation, scenario analysis, and predictive maintenance, especially in pharma manufacturing and automobile design.

Every leap in AI capability is underpinned by these basic technologies, turning vast data streams into actionable insights and improved operations.

Sector-Wise AI Integration Overview

AI integration differs by sector, with each business employing distinct applications to handle unique issues and possibilities.

- Manufacturing→ AI is utilized for predictive maintenance, production scheduling, supply chain optimization, and quality control. Manufacturers utilize AI to save downtime, eliminate faults, and improve overall equipment efficacy.

- Biotech→ In biotech, AI accelerates genome analysis, drug discovery, and tailored therapy. AI models evaluate complicated biological data, enabling speedier discovery of treatment targets and more precise therapies.

- Pharma→ AI impacts the pharma sector through drug development, clinical trial optimization, factory automation, and supply chain management. AI-driven simulations, predictive maintenance, and digital twins reduce procedures and increase product quality.

- Automotive→ The automobile industry employs AI for autonomous driving, predictive maintenance, smart manufacturing, and supply chain logistics. Computer vision enables real-time monitoring and decision-making in cars and factories.

From improving production to changing healthcare, AI’s inclusion in several industries is reshaping the future of industry worldwide.

AI in Manufacturing→ Use Cases and Examples

AI in manufacturing is transforming the sector by boosting efficiency, enhancing quality, and enabling smarter decision-making. From predictive maintenance to generative design, businesses are leveraging AI to enhance every element of manufacturing. The convergence of AI-powered robotics, machine vision, and advanced analytics is converting traditional factories into smart, adaptive ecosystems.

As manufacturing enters a new era, AI stands at the forefront-reshaping how things are developed, built, and delivered.

Top 10 Real-World Examples of AI in Manufacturing

| Use Case | Real-World Example | Impact/Outcome |

|---|---|---|

| Production Process Optimization | Automotive manufacturer uses generative AI for car design | Lighter, safer vehicles→ improved fuel efficiency |

| Additive Manufacturing (3D Printing) | Aerospace company uses AI to optimize part designs | 20% material cost reduction→ 30% faster production |

| Collaborative Robots (Cobots) | Electronics firm deploys AI-powered cobots on assembly lines | 30% efficiency boost→ 25% less setup time→ safer work |

| Machine Vision for Quality Control | Pharma company uses AI vision for packaging inspection | Higher accuracy→ reduced recalls→ improved standards |

| Automated Material Handling | Food & beverage company uses AI for raw material logistics | 25% routing efficiency→ 20% throughput increase |

| Demand Forecasting & Planning | Apparel manufacturer uses AI for sales predictions | 95% prediction accuracy→ 20% less excess stock |

| Digital Twins for Production Lines | Automotive company simulates assembly with AI-driven digital twins | 30% throughput increase→ 20% cycle time reduction |

| AI-Driven Defect Detection | Electronics firm uses computer vision for product flaw detection | 90% fewer false positives→ 50% more defect detection |

| Energy Efficiency Management | Siemens uses AI for factory energy optimization | Lower operational costs→ reduced environmental impact |

| Supply Chain Optimization | Shopper electronics firm uses AI for inventory management | 20% reduction in inventory holding costs |

These real-world examples demonstrate how AI in manufacturing is not simply a fad, but a catalyst for genuine operational gains and innovation.

AI in Biotech→ Accelerating Innovation

AI in biotech is boosting the speed of scientific discovery and enabling advances that were previously inconceivable. By evaluating complicated biological data, AI systems help uncover novel medication possibilities, optimize gene editing, and tailor therapies. This rapid innovation is converting biotech enterprises into nimble, data-driven organizations.

In biotech, AI is more than a tool-it’s a partner in discovery, opening doors to new cures and solutions at unprecedented speed.

Key Applications of AI in Biotech

| Application | Description | Example/Impact |

|---|---|---|

| Drug Discovery | AI screens vast compound libraries for potential drug candidates | Faster identification of viable molecules |

| Genome Analysis | AI interprets genomic data to identify mutations and targets | Improved diagnosis and personalized medicine |

| Protein Structure Prediction | Deep learning predicts complex protein folding | Accelerates vaccine and therapeutic development |

| Biomarker Discovery | Machine learning finds new disease markers in biological samples | Earlier, more accurate disease detection |

| Clinical Trial Optimization | AI analyzes patient data to design better trials | Higher trial success rates→ reduced costs |

| Synthetic Biology | AI models design and optimize synthetic genes and pathways | More efficient bio-manufacturing and innovation |

| Medical Imaging Analysis | AI interprets images for cell counting, tumor detection, etc. | Faster, more accurate lab results |

| Personalized Treatment Planning | AI tailors therapies to individual genetic profiles | Higher treatment efficacy→ fewer side effects |

Incorporation of AI in biotech is not only speeding research but also boosting the precision and effectiveness of new medical solutions, influencing the future of healthcare and life sciences.

AI in Pharma→ From Molecule to Market

Artificial intelligence (AI) is revolutionizing the pharmaceutical sector by expediting the route from chemical discovery to market approval. By integrating AI, pharma companies can evaluate huge chemical and biological databases, forecast therapeutic efficacy, and optimize every stage of the drug development process. This move is not only cutting costs and deadlines but also providing new options for personalized treatment and revolutionary medicines.

AI is reinventing what’s possible in pharma, making the process from lab bench to pharmacy shelf faster, smarter, and more efficient.

Drug Discovery to Clinical Trials→ Role of AI in Pharma

Influence of AI in pharma spans the entire lifecycle-from early-stage drug research to clinical trials and manufacturing→

- Drug Discovery→ AI algorithms swiftly screen millions of molecules, anticipate molecular interactions, and find the most promising possibilities. This accelerates the identification of effective medications and minimizes the likelihood of late-stage failures.

- Preclinical Development→ Machine learning models estimate toxicity and efficacy, helping researchers to pick molecules with the best therapeutic potential.

- Clinical Trials→ AI simplifies patient recruitment, location selection, and trial design. By evaluating electronic health records and real-world data, AI matches patients to trials more effectively, predicts outcomes, and monitors safety in real time.

- Manufacturing→ AI-driven technologies provide quality control, streamline production processes, and enable predictive maintenance, lowering errors and operational costs.

- Regulatory and Market Access→ AI aids regulatory submissions by organizing and analyzing trial data, while also enabling targeted marketing tactics and post-market surveillance.

From idea to approval, AI is at the basis of a more agile, data-driven pharmaceutical process.

Ai in Pharma: Tools Comparison

| Tool/Platform | Primary Application | Key Features | Example Impact |

|---|---|---|---|

| Atomwise | Drug discovery | Deep learning for molecular screening | Identified new drug leads in weeks |

| Exscientia | Molecule design & optimization | Generative AI for candidate design | Designed cancer drug in under 12 months |

| IBM Watson for Clinical Trials | Clinical trial optimization | Patient matching, site selection | Reduced recruitment time by 80% |

| BenevolentAI | Drug development | AI-driven hypothesis generation | Accelerated identification of targets |

| BioXcel Therapeutics | Clinical trial design | Predictive analytics, adaptive trials | Improved trial success rates |

| PathAI | Pathology analysis | AI-powered image diagnostics | Enhanced biomarker discovery |

| Deep 6 AI | Patient recruitment | Real-time EHR data mining | Faster, more accurate trial enrollment |

These AI platforms are not simply tools-they are catalysts, enabling pharma companies to develop rapidly, optimize trials, and bring treatments to patients faster than ever before.

AI in Automotive Industry→ Current and Future Impact

AI is revolutionizing the automotive sector by allowing smarter, safer, and more efficient automobiles and manufacturing processes. Leading automakers and technology corporations are investing extensively in AI-driven systems, particularly for autonomous vehicles and next-generation manufacturing. AI applications are altering everything from supply chain logistics to quality control, predictive maintenance, and the driving experience itself. As AI capabilities progress, the automotive sector is primed for more innovation-ushering in an era of connected, driverless, and highly adaptive automobiles.

The road forward for automotive AI is not just about automation, but about transforming how automobiles are built, maintained, and experienced.

Smart Vehicles and Autonomous Driving

AI is at the heart of smart vehicles and the push toward autonomous driving. Self-driving cars utilize a combination of sensors, cameras, lidar, and radar to see their environment, while advanced AI algorithms interpret this data to make real-time driving judgments. Companies like Tesla, Waymo, and GM are at the forefront, with vehicles capable of lane changes, parking, and even working as robo-taxis in select locations.

Recent developments in computer vision and object identification have increased vehicles’ ability to perceive traffic signs, pedestrians, and other hazards-even in adverse situations. AI also powers voice assistants and personalizes in-car experiences, from route planning to entertainment selections. As these technologies evolve, autonomous vehicles are likely to become more widespread, safer, and more reliable in complex traffic scenarios.

Smart vehicles are developing from simple transit to intelligent companions, adjusting to drivers’ needs and the road ahead.

AI in Automotive Manufacturing and Maintenance

| Application Area | Example/Technology | Impact/Outcome |

|---|---|---|

| Predictive Maintenance | BMW’s predictive cloud platform→ Volvo Trucks’ LightGBM model | Reduces unplanned downtime, extends machinery lifespan, cuts roadside incidents by 15% |

| Quality Control | Audi’s AI-driven visual inspection→ computer vision | Automated defect detection, real-time correction, higher quality standards |

| Design & Prototyping | Generative AI for rapid prototyping | Faster, more adaptive vehicle design, aligned with market trends |

| Personalized Maintenance | Volvo’s connected cars, UPS fleet analytics | Custom service alerts, optimized schedules, cost savings |

| Battery Health & Safety | Tesla’s GRU-based battery model, Mercedes-Benz AI | Early issue detection, safer charging, improved battery life |

| Supply Chain Optimization | AI-driven logistics and inventory management | Reduced holding costs, streamlined operations |

AI in automotive production offers real-time monitoring, predictive analytics, and process optimization. Machine learning models examine sensor data from equipment to anticipate errors, while computer vision systems boost quality control by spotting defects during production. Predictive maintenance solutions, such as those employed by BMW and Volvo Trucks, have greatly decreased downtime and enhanced reliability.

With AI, automotive manufacturing and maintenance are transitioning from reactive to proactive-ensuring vehicles and plants run at top performance.

Cross-Industry AI Benefits and Synergies

AI brings major benefits across manufacturing, biotech, pharma, and automotive by optimizing operations, boosting decision-making, and allowing data-driven innovation. Common advantages include→

- Efficiency Gains→ AI automates repetitive processes, optimizes workflows, and boosts resource allocation, leading to decreased costs and faster time-to-market across all sectors.

- Quality Improvement→ Machine learning and computer vision systems offer real-time monitoring and fault detection, boosting product quality and compliance standards.

- Predictive Capabilities→ AI models foresee maintenance needs, demand, and supply chain interruptions, saving downtime and waste.

- Personalization→ In biotech and pharma, AI aids customized medicine by evaluating genetic and clinical data for individualized therapies.

- Innovation Acceleration→ AI-driven analytics and simulations speed up research, product creation, and process optimization, boosting cross-sector innovation.

Adoption of AI in industrial sector is producing a network effect-each sector’s gains feed broader progress and new chances for collaboration.

Common AI Challenges Across These Industries

Despite its transformational potential, AI adoption faces numerous shared obstacles→

- Data Quality and Integration→ Industries struggle with fragmented, inconsistent, or biased data, impeding model accuracy and reliability.

- Transparency and Explainability→ Complex AI algorithms, especially deep learning, frequently operate as “black boxes,” making it difficult to comprehend judgments and assure confidence.

- Regulatory Compliance→ Navigating diverse, developing rules (e.g., GDPR, HIPAA, EU AI Act) demands robust governance and continual adaption.

- Talent dearth→ There is a global dearth of experienced experts to build, deploy, and maintain AI systems, limiting deployment.

- Change Management→ Integrating AI with legacy systems and overcoming organizational opposition are recurring problems.

- Security and Privacy→ Protecting sensitive data from breaches and ensuring ethical data use are significant considerations, especially in healthcare and pharma.

Addressing these problems is key for unlocking AI’s full potential across sectors.

Ethics and Governance in AI-Powered Sectors

Ethical and responsible AI use is a developing priority. Sectors are establishing governance frameworks to ensure→

- Transparency→ Clear documentation of AI models and decisions, enabling accountability.

- Fairness and prejudice Mitigation→ Regular audits and diversified data sets assist decrease prejudice and promote equal outcomes.

- Privacy Protection→ Strict data processing and compliance with privacy regulations secure personal and sensitive information.

- Stakeholder Engagement→ Involving ethicists, regulators, and affected communities ensures balanced, human-centric AI deployment7.

Leading firms are adopting concepts such as transparency, justice, and human-centricity, while planning for future restrictions like the EU AI Act7. Continuous monitoring and risk assessments are crucial to appropriate AI governance.

As AI’s influence grows, robust ethics and governance frameworks are essential for trust and sustainable innovation.

Future Trends in AI Across Manufacturing, Biotech, Pharma, and Automotive

Looking ahead, various trends are affecting the future of AI in certain sectors→

- Foundation Models and Generative AI→ Large, pre-trained models will fuel more adaptive, multi-purpose AI applications, from medication design to autonomous vehicles.

- Digital Twins→ Virtual replicas of assets and processes will enable real-time simulation, optimization, and predictive maintenance across industries6.

- Personalized Production→ AI will assist highly personalized products and therapies, especially in biotech and pharma, through sophisticated analytics and automation.

- Edge AI and IoT Integration→ Deploying AI at the edge-closer to sensors and devices-will increase real-time decision-making in manufacturing and automobiles.

- Stronger Regulation and Governance→ Anticipated rules will standardize AI development and deployment, stressing safety, transparency, and responsibility.

- Interdisciplinary Collaboration→ Cross-sector relationships will expedite innovation, utilizing shared data, tools, and skills for broader effect.

AI’s trend points toward deeper integration, greater customisation, and heightened emphasis on ethics and collaboration-reshaping industry landscapes worldwide.

Query→ What AI pilots they are going to run or would like to run in 2025

Sector-Wise AI Pilots to Watch

In 2025, AI in manufacturing, biotech, pharma, and automotive are focused on practical, high-impact deployments. These pilots are meant to address sector-specific difficulties and uncover new efficiencies, with many initiatives advancing from experimental to operational phases.

Manufacturing→ AI Pilots Planned for 2025

- Predictive Maintenance at Scale→ Manufacturers are introducing AI-driven predictive maintenance pilots to decrease downtime and extend equipment life. These experiments employ IoT data and machine intelligence to anticipate errors before they occur.

- AI-Driven Quality Control→ Computer vision pilots are being expanded for real-time defect detection and automated inspection, aiming to increase quality and reduce manual labor.

- Generative Design and Simulation→ Companies are experimenting generative AI technologies for rapid prototyping and digital twins, enabling for speedier product creation and process optimization.

- AI in Supply Chain Optimization→ New pilots focus on AI-powered demand forecasting and logistics, boosting inventory management and saving costs.

For more on manufacturing AI pilots, see Frugal Testing’s 2025 AI software testing trends.

Biotech→ Experimental AI Projects

- Foundation Models for Biology→ Biotech corporations are piloting large-scale AI models trained on multi-omics datasets to reveal new genetic patterns, predict biomarkers, and accelerate drug discovery. Early results offer potential in discovering novel treatment targets.

- AI-Accelerated Protein Engineering→ Startups and research labs are undertaking pilots to leverage AI for protein structure prediction and engineering, accelerating vaccine and treatment development.

- Precision Agriculture and Synthetic Biology→ AI pilots are ongoing to maximize agricultural yields and develop synthetic genes, with machine learning models driving experimental design and analysis.

Explore biotech AI pilots in detail at StartUs Insights and BioLizard’s 2025 predictions.

Pharma→ Clinical AI Trials Coming Up

- AI-Driven Patient Recruitment→ Pharma companies are exploring AI tools to connect patients to clinical trials using electronic health records, enhancing recruitment speed and diversity.

- Digital Twin Trials→ Pilots are employing AI-generated digital twins to imitate patient responses, lowering the number of participants needed and enhancing trial design.

- Real-Time Data Analysis→ New pilots employ AI for continuous monitoring and adaptive trial protocols, hoping to minimize trial durations and costs while increasing outcomes.

For further reading, see Drug Target Review’s 2025 pharma AI overview and Clinical Leader’s market trends.

Automotive→ AI Integrations in Testing Phase

- Driverless Driving Algorithms→ Automakers are piloting enhanced AI for perception, decision-making, and safety compliance in driverless vehicles. These pilots focus on real-world testing and integration with industry safety standards.

- AI-Enhanced Software Quality Assurance→ Automotive software teams are running pilots employing AI-driven tools for automated testing, defect prediction, and compliance with standards like MISRA and ISO 21434.

- Generative Design in R&D→ R&D departments are exploring generative AI for simultaneous design and testing of vehicle components, intending to shorten development cycles and enhance innovation.

For more details, visit Perforce Software’s 2025 automotive AI report and Oliver Wyman’s principles for scaling automotive AI.

These sector-specific AI pilots reflect a shift toward practical, scalable solutions in 2025, with each industry leveraging AI to address its most pressing challenges and opportunities.

Top AI Tools and Platforms by Industry

| Industry | Tool/Platform | Core Application | Source Link |

| Manufacturing | Siemens MindSphere | Industrial IoT, predictive maintenance | Siemens MindSphere |

| Manufacturing | IBM Maximo | Asset management, AI-driven maintenance | IBM Maximo |

| Biotech | Deep Genomics | Drug discovery, genomics | Deep Genomics |

| Biotech | Benchling | Data management for biotech R&D | Benchling |

| Pharma | Atomwise | AI-powered molecular screening | Atomwise |

| Pharma | Exscientia | Generative AI for drug design | Exscientia |

| Pharma | PathAI | AI-powered pathology analysis | PathAI |

| Automotive | NVIDIA DRIVE | Autonomous driving platform | NVIDIA DRIVE |

| Automotive | Tesla Autopilot | Advanced driver-assistance system | Tesla Autopilot |

| Automotive | Siemens NX | Digital twin, generative design | Siemens NX |

These platforms are important to the digital transformation of their respective industries, enabling smarter operations and innovation.

Expert Opinions on AI Adoption in Industrial Sectors

Industry experts stress that AI is fast becoming indispensable in manufacturing, biotech, pharma, and automotive. According to BioPharm International, Ben Sidders from Biorelate says that AI in pharma is predicted to exceed $3 billion in spending by 2025, with collaborations for AI-driven drug discovery expanding tenfold between 2015 and 2021. AI-first biotech organizations are leading the way, with 75% integrating AI deeply into their processes, while traditional pharma is catching up as digital transformation becomes a must. PwC reports that 53% of pharma finance leaders are emphasizing AI and analytics to automate and rethink operations from the ground up. Read more at BioPharm International and Coherent Solutions.

In manufacturing, experts emphasize the role of AI in predictive maintenance and quality control, projecting up to $10 billion in cost savings by 2030 due to reduced unplanned downtime. Impact of AI in automotive is similarly profound, with leading analysts forecasting rapid expansion of autonomous driving pilots and AI-driven manufacturing optimization. For more, see EOXS and StartUs Insights.

Expert consensus is clear→ AI adoption is not just a trend but a fundamental shift in how industrial sectors operate and innovate.

Case Studies→ Successful AI Implementations

- AlphaFold in Pharma→ DeepMind’s AlphaFold has revolutionized protein structure prediction, achieving near-experimental accuracy and accelerating drug discovery for complex diseases. Read more

- Novartis in Biopharma Manufacturing→ Novartis uses AI-driven analytics to monitor production in real time, detecting quality issues early and automating quality checks, resulting in faster, more reliable manufacturing. Read more

- Samsung Electronics in Semiconductor Manufacturing→ Samsung integrated AI for real-time monitoring and anomaly detection, improving product yield, reducing defect rates, and minimizing downtime. Read more

- Sanofi in Pharma Supply Chain→ Sanofi leverages generative AI to digitize quality assessment and optimize supply operations, achieving accurate inventory predictions and improved efficiency. Read more

- AI in Biomanufacturing→ Companies are using digital twins and AI for process modeling, strain engineering, and fermentation optimization, leading to higher yields and reduced costs. Read more

- Merck in Pharmaceutical Quality Control→ Merck adopted AI to analyze manufacturing data, streamlining processes and ensuring compliance with regulatory standards. Read more

These case studies highlight how AI is generating demonstrable gains in efficiency, quality, and innovation across industries.

How to Get Started with AI in Your Sector

Adopting AI in manufacturing, biotech, pharma, or automotive begins with a defined digital strategy and a robust data foundation. Start with digitizing essential operations to ensure clean, structured data-this is crucial for efficient AI adoption. Assess your present digital infrastructure, identify important business concerns, and prioritize areas where AI may bring real value, such as predictive maintenance, quality control, or supply chain efficiency. Collaborate with technology partners, engage in staff training, and consider pilot initiatives to test AI’s impact before growing.

AI adoption is a journey-building the appropriate foundation today lays the platform for dramatic development tomorrow.

AI Readiness Checklist for Businesses

| Step | Key Actions | Resources/Links |

| Digital Infrastructure | Digitize operations, implement IoT, ensure data capture | Why factories need a digital backbone before embracing AI |

| Data Quality & Availability | Clean, organize, and standardize data; adopt FAIR principles | Scilife: AI in Pharma Challenges |

| Clear Business Objectives | Identify specific use cases and KPIs for AI projects | Matellio: AI Transformation |

| Regulatory Compliance | Ensure adherence to industry regulations (GDPR, HIPAA, etc.) | SCW.AI: AI in Pharma |

| Skilled Workforce | Upskill teams in data science, AI, and change management | SCW.AI: AI in Pharma |

| Integration & Change Management | Plan for seamless integration with legacy systems; manage organizational change | SCW.AI: AI in Pharma |

| Pilot Projects & Evaluation | Start with small pilots, measure ROI, iterate and scale | Frugal Testing: AI Trends 2025 |

Following a methodical checklist increases the likelihood of effective AI integration and long-term commercial value.

FAQs about AI in Manufacturing, Biotech, Pharma, and Automotive

- Q→ What is the first stage for AI use in manufacturing?

A→ Begin by digitizing operations and ensuring high-quality, organized data is available for AI applications. - Q→ How does AI boost efficiency in biotech and pharma?

A→ AI accelerates data analysis, drug development, and process optimization, enabling faster, more precise research and manufacture. - Q→ What are the primary challenges of AI in industrial sectors?

A→ Key issues include data quality, regulatory compliance, interaction with legacy systems, and the requirement for skilled people. - Q→ How can organizations overcome AI’s “black box” problem?

A→ By employing explainable AI tools, implementing standards like ONNX, and following best practices for model transparency. - Q→ Is AI only for huge enterprises?

A→ No, AI solutions are increasingly accessible to small and medium-sized organizations through cloud platforms and industry alliances.

AI’s potential is vast-clear answers and best practices help businesses navigate the road with confidence.

Conclusion→ Is AI the Future Backbone of Industry?

AI is rapidly becoming the backbone of modern industry, driving efficiency, innovation, and competitiveness across manufacturing, biotech, pharma, and automotive sectors. Its ability to automate difficult activities, analyze large datasets, and give actionable insights is altering business models and allowing new levels of efficiency. While difficulties remain-such as data quality, regulatory compliance, and workforce readiness-ongoing breakthroughs in AI technology and best practices are making adoption more possible and impactful than ever.

As sectors continue to digitize and adopt data-driven decision-making, AI will be key to creating the future of global business.